Plasticizer: chemicals additives which are introduced into concrete mix to perform 2 key function

- To reduce the amount of water in the mix, hence the capillary porosity of the hardened cementitious materials.

- To maintain a specified workability of the fresh concrete for reasonable period of time even at low water /cement ratio (W/C)

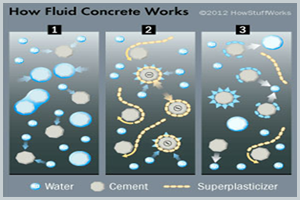

The plasticizer generally go into reaction only with binder(cement) when its add to concrete . It is absorbed by the particles of the binder. The particles push each other by electrostatic force .thus the desired workability obtained by less amount of water . Proportional with decrease of mixtures water amount mechanic strength increases.The concrete admixtures classifies as below according to (ASTM C494,C1017).

Additives are classified as types according to ASTM C494, C1017 and as follows:

- Type A (water reducer)-WR

- Type B (set retarder)-R

- Type C (accelerating)-A

- Type D (water reducer &retarder)-WR+R

- Type E (water reducer and accelerating)-WR+A

- Type F (high water reducer and super plasticizer)-HWR+SUPERPLASTICIZER

- Type G (high range water reducing &retarding admixtures super plasticizer)-HWR+R

The recommended uses for the plasticizer For concrete class C 18 – C 25

- (WR) water reducer type A with temp between 5C◦ to 30C◦

- (WR) +retarder type D with temp >30C◦

- (WR)+ Setting accelerator type E with temp. <5C◦

For concrete class C 30 & upper

- (HRWR) high range water reducer when temp between 5C◦ -30C◦

- (HRWR)+accelerator when temp>5C◦

- (HRWAR)+retarding when temp <30C◦ And can used plasticizer Type D,E,G

Dosage :commonly 0.75-1.5 kg for 100 kg of cement

Please request the products data sheet and read it carefully before use,and

don’t hesitate for contacting us for any help and request.

Set accelerators:

Admixture which decrease the time to commencement of the transition of the mix from the plastic to rigid state.

Hardening Accelerating Admixture which increases the rate of development of early strength in concrete with or without effecting in setting time

Air Entrain Admixture

Its oil alcohol & ammonium salt based air entraining concrete admixture that forms permanent ,small and optimum separated air bubbles by entraining controlled air into concrete and increases its strength against freeze thaw cycle , enable optimally separated air porosity system ,enable durability and low permeability due low w/c reduce segregation ,improve workability.

Light Weight Concrete Admixture

Chemicals in liquid form used with light aggregates and perlite for light weight which used as insulation mortar and used in foaming generator for making concrete foam screed.

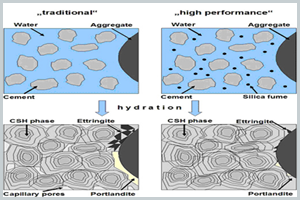

Silica Fume

micro-silica fume to produce high-strength or high-performance concrete. Silica fume affects hardened concrete by promoting early strength and reducing permeability, potential for alkali-silica reaction and drying shrinkage. It also increases resistance to sulfate attack

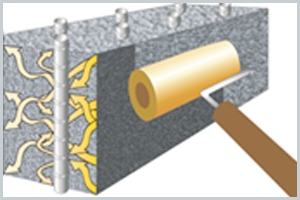

Water Proof Concrete Admixture

which used to decrease the capillary absorption of hardened concrete and getting tight concrete less permeable

Shrinkage Reducer Admixture

Improve the cohesion in the pore space due to length change of water loss , impermeability & highly reduce the dry shrinkage.

Corrosion Inhibitor

Its chemical use as coat for rebar and some grade s add to dry mix concrete to work as cathode protection

Pumping Concrete Admixture

Admixture which reduce the loss of water by reduction of bleeding

Under Water Concrete Stabilizer Added to concrete to increase alkali resistance and avoider segregation cement paste

Fiber for Control Cracks in Concrete

its fine fiber from glass or polypropylene treated to be disperse easily in concrete matrix to improve cohesion of fresh concrete with less cracks due to shrinkage ,high impact resistance and water proofing.

Expanding Aids Admixture

Introducing micro bubbles into mix and increased fluiditywithoutsegregation using in rock &soil anchoring ,pre stressed cable ducts.